In today’s electronics industry, precision is no longer optional. As electronic devices become smaller, smarter, and more complex, the plastic components inside them must meet extremely tight tolerances, deliver consistent electrical performance, and withstand heat, vibration, and long-term use.

This is where precision injection molding for electronics applications plays a critical role.

From connectors and sensor housings to micro enclosures and insulating components, precision molding enables electronics manufacturers to produce high-quality plastic parts at scale, without compromising dimensional accuracy or reliability.

This article explores how precision injection molding supports electronics manufacturing, the materials involved, design considerations, quality standards, and why choosing the right molding partner matters.

What Is Precision Injection Molding?

Precision injection molding is a specialized manufacturing process focused on producing plastic parts with:

- Extremely tight tolerances (often ±0.01 mm or tighter)

- High repeatability

- Excellent surface finish

- Consistent material properties

Unlike standard injection molding, precision molding places greater emphasis on:

- Advanced mold design

- Process control and monitoring

- High-performance materials

- Tooling accuracy

- Quality inspection systems

For electronics applications, these factors are essential to ensure proper fit, electrical insulation, mechanical stability, and long-term performance.

Why Precision Matters in Electronics Applications

Electronic components are sensitive by nature. A slight dimensional deviation can cause:

- Poor connector mating

- Electrical shorts

- Signal interference

- Heat buildup

- Assembly failures

- Reduced product lifespan

Precision injection molding ensures that plastic parts integrate seamlessly with electronic systems and meet strict industry standards.

Key Requirements in Electronics Molding

Electronics components typically require:

- Tight dimensional tolerances

- Stable dielectric properties

- Heat resistance

- Flame retardancy

- Low warpage and shrinkage

- Clean, defect-free surfaces

Precision molding addresses all these challenges through controlled tooling, optimized processing, and material selection.

Common Electronics Components Made by Precision Injection Molding

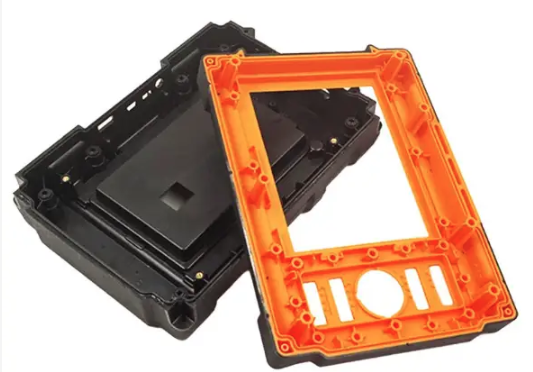

Precision injection molding is widely used across consumer electronics, industrial electronics, automotive electronics, and medical electronics.

Typical Molded Electronics Parts

- Electrical connectors and terminals

- Sensor housings

- Switch components

- Micro enclosures

- Insulating parts

- LED housings and lenses

- Battery cases

- Coil bobbins

- PCB supports and frames

- Cable management components

Many of these parts are small, thin-walled, and geometrically complex, making precision molding the most reliable production method.

Materials Used in Precision Injection Molding for Electronics

Material selection is one of the most critical decisions in electronics molding. The right plastic must offer mechanical strength, thermal stability, and electrical insulation, while maintaining dimensional accuracy.

Common Thermoplastics for Electronics

ABS (Acrylonitrile Butadiene Styrene)

- Good dimensional stability

- Easy to mold

- Cost-effective

- Suitable for housings and enclosures

Polycarbonate (PC)

- High impact strength

- Excellent transparency (for lenses)

- Good heat resistance

- Used for LED covers and protective parts

Nylon (PA6 / PA66)

- Strong mechanical properties

- Heat resistant

- Excellent wear resistance

- Common in connectors and structural components

PBT (Polybutylene Terephthalate)

- Excellent electrical insulation

- Low moisture absorption

- Good dimensional stability

- Widely used in connectors and coil bobbins

PET

- Good chemical resistance

- Stable dielectric properties

- Used in precision electronic components

High-Performance Engineering Plastics

For demanding electronics applications, advanced materials are often required:

- PPS – High temperature resistance, excellent electrical properties

- PEEK – Extreme heat resistance, chemical stability

- LCP (Liquid Crystal Polymer) – Ultra-low shrinkage, ideal for microelectronics

- PA46 / PA9T – High heat deflection, excellent flow for thin walls

Many electronics-grade materials are available in flame-retardant (UL94 V-0) formulations to meet safety standards.

Mold Design Considerations for Electronics Precision Molding

High-precision electronics parts start with exceptional mold design.

Key Mold Design Factors

Tight Tolerance Control

- Precision CNC machining

- EDM finishing

- Mold alignment accuracy

- Temperature-controlled mold bases

Gate Design

- Minimizes weld lines

- Reduces stress and burn marks

- Ensures uniform flow for thin walls

Venting

- Prevents trapped air

- Reduces short shots and surface defects

- Critical for micro and thin-wall parts

Cooling System

- Uniform cooling to prevent warpage

- Improves cycle time

- Enhances dimensional stability

Mold Steel Selection

- High-hardness steel for long tool life

- Polished cavities for clean surfaces

- Corrosion-resistant materials for flame-retardant resins

For electronics, even minor mold imperfections can affect part performance, making precision tooling essential.

Thin-Wall and Micro Injection Molding for Electronics

Modern electronic devices demand smaller and lighter components, driving the need for thin-wall and micro injection molding.

Thin-Wall Electronics Molding

- Wall thickness often below 1.0 mm

- Requires high-flow materials

- Demands high injection speed and pressure

- Requires precise temperature control

Micro Injection Molding

- Part weights measured in milligrams

- Extremely tight tolerances

- Specialized micro molds and machines

- Used for micro connectors, sensors, and medical electronics

Precision injection molding technology makes it possible to produce these components consistently and at scale.

Process Control in Precision Injection Molding

Achieving precision is not just about the mold—it’s about process control.

Key Process Parameters

- Injection speed and pressure

- Melt temperature

- Mold temperature

- Cooling time

- Holding pressure

- Screw position accuracy

Advanced electronics molding facilities use:

- Closed-loop process control

- Scientific molding techniques

- Real-time monitoring

- Automated parameter adjustments

This ensures consistent quality across every production run, even for high-volume electronics manufacturing.

Quality Standards and Testing for Electronics Components

Electronics manufacturers operate under strict quality requirements.

Common Quality Standards

- ISO 9001 – Quality management

- ISO 14001 – Environmental management

- IATF 16949 – Automotive electronics

- RoHS and REACH compliance

- UL certification for flame retardancy

Inspection and Testing Methods

- CMM dimensional inspection

- Optical measurement systems

- Electrical insulation testing

- Heat aging tests

- Mechanical strength testing

- Appearance and surface inspection

Precision injection molding suppliers for electronics must maintain robust quality systems to meet global compliance requirements.

Advantages of Precision Injection Molding for Electronics

Choosing precision injection molding offers multiple benefits for electronics manufacturers.

Key Advantages

- High-dimensional accuracy

- Excellent repeatability

- Suitable for complex geometries

- Scalable from prototype to mass production

- Superior surface finish

- Consistent electrical and mechanical performance

- Lower defect rates

- Reduced assembly issues

These advantages translate directly into higher product reliability and lower overall manufacturing costs.

Prototyping and Low-Volume Electronics Production

Precision injection molding is not limited to mass production.

Applications in Prototyping

- Functional prototypes

- Pilot production runs

- Design validation

- Market testing

Using aluminum molds and optimized tooling, manufacturers can produce high-precision electronic parts quickly, without the cost of full-scale production tooling.

Choosing the Right Precision Injection Molding Partner

Not all molding suppliers are equipped for electronics precision molding.

What to Look For

- Experience in electronics applications

- Advanced tooling capabilities

- Material expertise

- Tight tolerance control

- Clean manufacturing environment

- Strong quality management systems

- Engineering and DFM support

A reliable precision molding partner works as an extension of your engineering team, helping optimize designs for manufacturability and long-term performance.

Future Trends in Electronics Precision Injection Molding

As electronics continue to evolve, precision molding technology is advancing alongside it.

Key Industry Trends

- Miniaturization of components

- Increased use of high-performance polymers

- Integration of molding and assembly

- Automation and smart manufacturing

- Higher demand for sustainability and recyclable materials

- Multi-material and insert molding for electronics

Precision injection molding will remain a core manufacturing technology for next-generation electronics.

Conclusion

Precision injection molding for electronics applications is the foundation behind many of the devices we rely on every day. From smartphones and sensors to industrial controllers and automotive electronics, precision-molded plastic components ensure accuracy, safety, and reliability.

By combining advanced materials, high-precision tooling, controlled processes, and strict quality standards, precision injection molding delivers consistent, high-performance components that meet the demanding requirements of modern electronics.

For electronics manufacturers seeking dependable quality, tight tolerances, and scalable production, precision injection molding is not just a manufacturing option—it’s a competitive advantage.